TAKE A TOUR

MODULE 1

-

THE KNOCK ROOM • THE EVISCERATION ROOM • THE QUICK CHILL FREEZER

THE KNOCK ROOM:

The Knock Room is designed for safe handling following strict USDA federal inspection requirements where we harvest the animal, bleed the animal and get them on a rail or rollers.

Walk through the green doors to the second room of Module 1…

-

THE EVISCERATION ROOM:

The carcass then rolls into the Evisceration Room where we skin them, gut them, clean them to federally inspected, zero tolerance policy. In the Evisceration Room, we split the carcass in half and connect it to the Vista Track temperature system for monitoring the internal temperature of the carcass.

-

THE QUICK CHILL FREEZER:

Once the carcass is split in half, it goes into the Quick Chill Room which brings the body temperature of the carcass down to 42°. It will stay in the Quick Chill Room overnight after harvest.

MODULE 2

-

THE AGING COOLER:

In the second module, the Dry Aging Cooler, there are three rails designed to hold 150 halves of protein; one rail is a bypass rail, where we can rotate through or bring any carcass forward quickly rather than shifting the whole cooler for the dry aging.

The carcass will hang between 7-23 days or as specified by the livestock grower as to how long they would like to have the carcass hung.

This module is also set up with the Vista Track temperature sensor, which logs all the temperatures of each carcass and tracks the moisture consistency of the protein.

MODULE 3

-

THE CUT & WRAP ROOM

The Cut and Wrap room is where the protein is taken off the bone. We have a double grinding system where we are able to load up the meat scraps, add them into the first burger grinder which grinds the scraps into the second burger grinder, which brings out the finished product of ground protein.

The protein goes into the Risco Packaging stuffer placing the finished product in one-pound packages which will be sent to Montana Food Bank Network.

For our custom processing individuals, we have a Patty-O-Matic machine that allows us to vacuum seal the steaks and primal cuts if desired.

Keeping up with USDA federal inspection and regulations, this unit is designed to keep tools and equipment clean. We have a commercial dishwasher for all equipment to be properly sanitized.

MODULE 4

-

THE FREEZER UNIT:

The Freezer Unit is where our end product is stored.

Our freezer unit was designed from the box backward — meaning all the dimensions of this entire processing unit were decided on around the size of our storage boxes, courtesy of Montana Food Bank Network (MFBN). We did this to eliminate extra handling.

The freezer units/fans you see in the ceiling are powerful enough to freeze packaged protein and keep it frozen in the box.

This unit is also designed for storing full pallets, which allows MFBN to back their semi-truck up and load directly from the freezer.

Once our protein leaves this unit, it will be distributed across the state of Montana by MFBN to those in need.

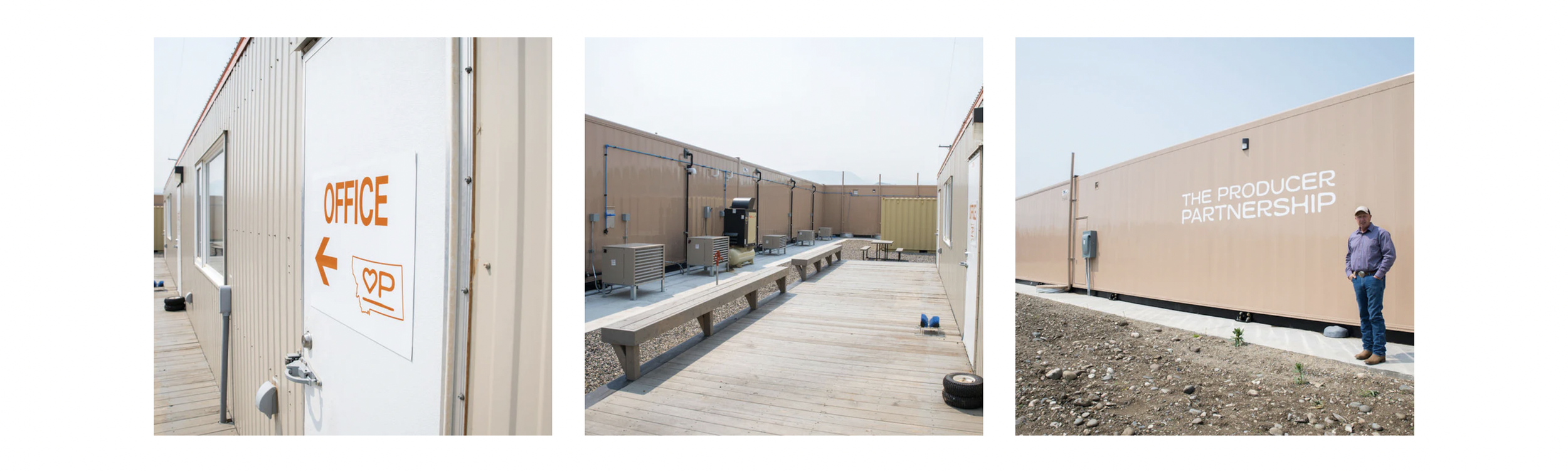

THE OFFICE

-

Our office building currently serves our employees and our USDA inspector. The office meets all USDA office regulations.

In the near future, we plan to have a meat processing school in partnership with Miles Community College (Miles CC). The office building will turn into student housing for the program.

Students will spend half their day in a classroom setting, learning meat processing and then will apply their training in our federally inspected processing unit the other half of the day.

When they graduate from our program, they will have the skills and knowledge to work at a processing facility.

THE GROUNDS

FACILITY VIDEO TOUR